Meetings in manufacturing environments are not optional extras. They are woven into the rhythm of factory life, from daily shift handovers and production huddles to weekly safety briefings and maintenance reviews. When done well, these meetings align teams, reinforce safety standards, and drive continuous improvement.

But when done poorly, meetings can become time drains that pull operators off the shop floor, delay production schedules, and create frustration. In fact, unplanned downtime continues to cost manufacturers up to 11% of their annual revenue, underscoring how even minor inefficiencies, like unnecessarily long or misaligned meetings, can ripple through profitability.

The good news is that manufacturing meetings can be redesigned to deliver clarity, efficiency, and accountability. By applying a structured approach and leveraging data-driven insights, organizations can ensure that meetings support operations rather than hinder them.

This article explores the common challenges of manufacturing meetings, practical steps to run them effectively, and how analytics tools can help leaders continuously improve their meeting culture.

Common Challenges in Manufacturing Meetings

Despite their importance, manufacturing meetings often suffer from predictable problems. For context, U.S. manufacturers lose approximately $50 billion annually from downtime, with as much as 15% of total manufacturing output lost directly due to such disruptions:

- Recurring meetings that run on autopilot: Safety briefings, shift handovers, and planning sessions often continue out of habit without reviewing whether they still add value.

- Lengthy discussions that eat into shift productivity: Operators are pulled away from the line for too long, reducing output.

- Unclear follow-up on safety or quality issues: Problems are discussed but not assigned to specific owners, leaving risks unresolved.

- Low engagement: Meetings are treated as 'tick-box exercises,' with participants present but disengaged.

- Poor time discipline: Meetings run long, overlap with production schedules, or clash with deep maintenance work.

- Lack of visibility across shifts: Issues raised in one shift’s meeting don’t always carry forward to the next, creating gaps in continuity.

Recognizing these challenges is the first step. The next is to replace them with intentional practices.

Practical Tips for Running Effective Manufacturing Meetings

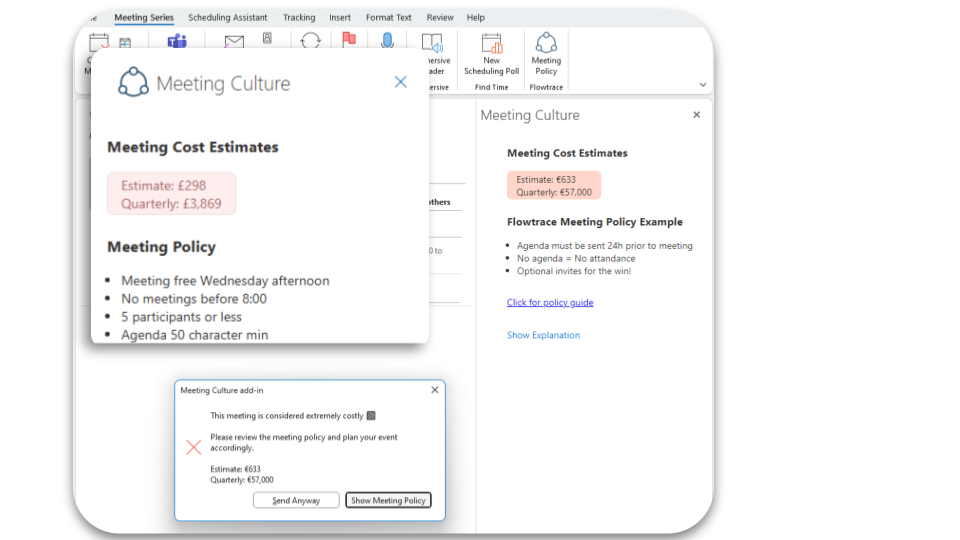

Standardize with Meeting Policies

Manufacturing thrives on repeatable processes, and meetings should be no different. Clear policies prevent wasted time and ensure consistency across shifts, plants, and teams.

Effective policies include:

- Agenda-or-cancel: No agenda, no meeting.

- Timeboxing: Limit discussions to fixed durations to avoid drift.

- Action-item requirement: Every issue raised must be assigned an owner and timeline.

Standardization ensures that whether it’s a safety briefing or a shift handover, meetings are predictable, structured, and purposeful.

Keep Daily Stand-Ups Short and Focused

Daily production huddles or shift handovers are essential, but they must be sharp. These meetings should run for no longer than 10–15 minutes and focus on three key points:

- Yesterday’s performance (output, downtime, defect rates).

- Today’s plan (production goals, shift targets).

- Risks and issues (safety concerns, supply delays, equipment problems).

Using visual management tools such as whiteboards or digital dashboards helps keep discussions focused and accessible to all participants.

Review Recurring Meetings Regularly

Weekly production reviews, monthly maintenance sessions, or cross-departmental syncs often become entrenched without evaluation. Leaders should audit recurring meetings quarterly, asking:

- Does this meeting still deliver value?

- Could it be shortened or reduced in frequency?

- Can async dashboards or updates replace parts of the meeting?

Recurring meetings that no longer serve a purpose should be redesigned or canceled to reclaim valuable time.

Balance Shop Floor and Office Time

One of the biggest tensions in manufacturing meetings is the trade-off between time spent in discussion and time on the line. Operators, engineers, and supervisors should not be locked in meetings that aren’t relevant to their roles.

Tips include:

- Keep shop-floor teams in meetings only for the segments relevant to them.

- Avoid long presentations; replace them with async updates or posted dashboards.

- Ensure meetings add value to the day’s work rather than pulling people away from it.

Async channels, such as digital signage, shift logs, or shared platforms, help reduce unnecessary meeting attendance.

Prioritize Safety and Quality

Safety meetings are among the most critical in manufacturing. They should never feel rushed or perfunctory.

Best practices include:

- Highlighting recent incidents or near misses.

- Reviewing compliance updates and procedural changes.

- Documenting every safety issue with an assigned owner and timeline.

The same principle applies to quality reviews: issues must be logged, tracked, and revisited until resolved. Safety and quality meetings should be seen as problem-solving forums, not checklists.

Assign Roles for Engagement

Engagement in manufacturing meetings often drops when the same leaders dominate the discussion. Rotating roles can prevent disengagement:

- Facilitator: Keeps discussion balanced across operators, supervisors, and managers.

- Timekeeper: Ensures meetings don’t overrun and that production schedules are protected.

- Note-taker: Captures decisions and action items in real time.

Giving operators opportunities to lead or contribute signals that their voices matter and surfaces problems earlier.

Use Data and Visual Management

Manufacturing thrives on data, and so should its meetings.

- Bring operational metrics such as OEE (overall equipment effectiveness), downtime, and defect rates directly into the meeting.

- Use visual boards or dashboards so problems are immediately visible.

- Compare performance across shifts to ensure accountability.

When data is central to the discussion, meetings stay grounded in facts rather than drifting into speculation.

Follow Up with Accountability

The most common failure point in manufacturing meetings is lack of follow-through. If safety hazards, quality issues, or maintenance problems are raised without resolution, trust erodes quickly.

Best practices include:

- Assigning a named owner for each action item.

- Reviewing unresolved items at the start of the next meeting.

- Using digital logs or shared platforms to ensure visibility across shifts.

Clear accountability ensures that meetings drive outcomes rather than endless discussions.

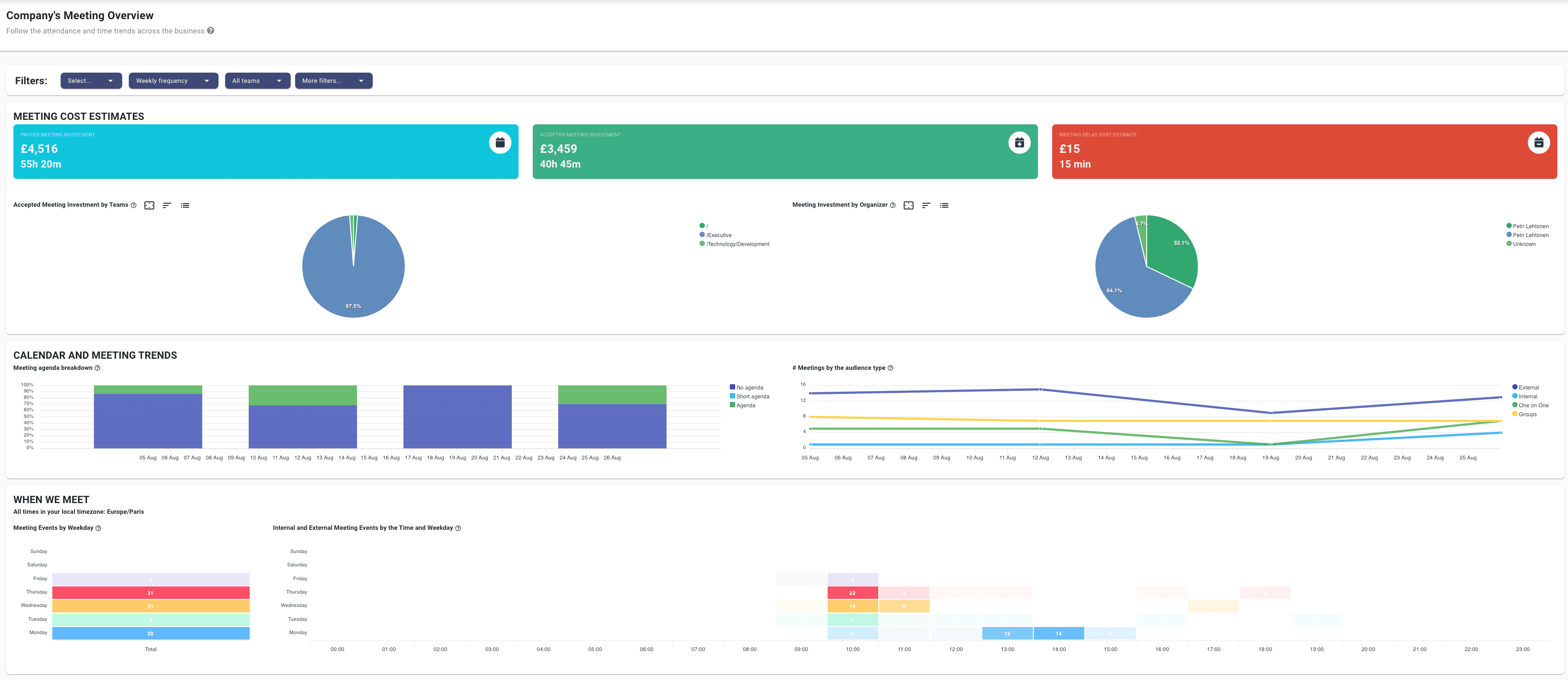

Review Meeting Load with Analytics

Even in manufacturing environments, leaders are often unaware of how much time is consumed by meetings. By reviewing calendar analytics, they can identify:

- Meeting hotspots: functions or roles overloaded with sessions.

- Recurring meeting costs: the financial impact of pulling multiple operators off the floor.

- Participation patterns: who contributes actively vs who is passively attending.

Making meeting costs visible reframes them from “just another half-hour' to real investments of time and money.

The Business Case for Effective Manufacturing Meetings

Running better meetings in manufacturing settings has direct impact:

- Improved shift continuity: Clear handovers reduce errors and downtime.

- Higher productivity: Shorter, sharper meetings free operators for production.

- Stronger safety culture: Documented and tracked safety actions reduce incidents.

- Accelerated problem-solving: Structured follow-up ensures quality issues are resolved quickly.

In manufacturing, where downtime directly impacts revenue, the stakes are even higher.

How Analytics Tools Like Flowtrace Help in Manufacturing

Even when best practices are adopted, leaders often lack visibility into whether meetings are delivering value.

Analytics platforms close this gap by:

- Tracking recurring meeting series across maintenance, safety, and production.

- Making costs visible by quantifying the time and salary impact of meetings.

- Analyzing participation to see whether the right people are in the room.

- Highlighting async opportunities, such as moving reporting out of daily huddles.

- Providing feedback loops so operators and supervisors can rate meeting usefulness.

For manufacturing leaders, this means meetings can be treated like any other operational process: measured, improved, and optimized.

Run Better Manufacturing Meetings Today

Manufacturing meetings are essential to keep production running smoothly, but without structure, they can erode productivity, safety, and morale. By standardizing policies, keeping stand-ups short, reviewing recurring sessions, balancing shop floor time, prioritizing safety, and using analytics, organizations can transform meetings from a burden into a driver of operational excellence.

When every minute counts, effective meetings are not just a cultural win, they are a competitive advantage.

FAQ